Understanding Galvanized Steel and Its Benefits

Galvanized steel is a form of steel that has undergone a protective process to prevent corrosion, significantly extending its lifespan and durability. This process involves coating the steel with zinc, either through hot-dip galvanizing or electro-galvanizing. In hot-dip galvanizing, the steel is immersed in molten zinc, creating a robust bond that results in a thick, corrosion-resistant layer. Electro-galvanizing, on the other hand, applies a thinner zinc coating through an electrochemical process. Both methods create a barrier that protects the underlying steel from moisture and other corrosive elements.

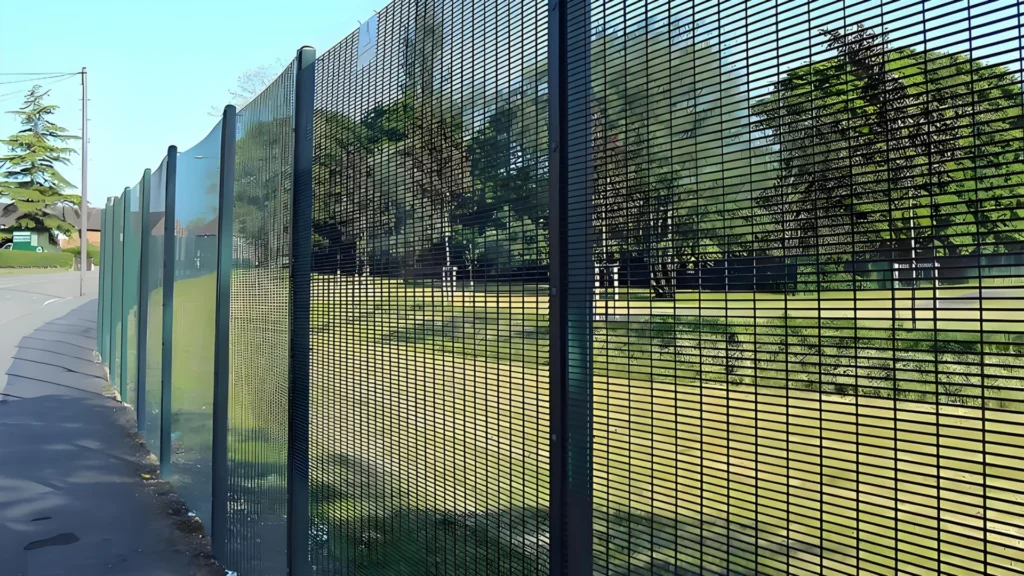

The benefits of galvanized steel fencing are particularly pronounced in environments that experience high levels of humidity, salt exposure, or industrial pollutants, such as coastal areas and industrial sites. The galvanized coating acts as a sacrificial layer; even if it becomes scratched or damaged, the underlying steel remains protected as the zinc will corrode preferentially. As a result, galvanized steel fencing can withstand the harsh conditions typical of these environments, reducing the need for frequent maintenance and replacement.

Furthermore, galvanized steel boasts an impressive durability, often lasting two to three times longer than untreated steel. This durability not only contributes to long-term cost savings but also enhances the structural integrity of construction projects. The corrosion resistance of galvanized steel ensures that it retains its aesthetic appeal over time, remaining functional and visually appealing even after years of exposure to challenging conditions.

In conclusion, the use of galvanized steel fencing in coastal and industrial construction projects is an intelligent choice, given its resilience against corrosion and rust, longevity, and low maintenance requirements. As such, investing in galvanized steel is not only practical but also beneficial for the success of various construction endeavors.

Why Choose Galvanized Steel Fencing for Coastal Projects

Coastal construction projects face unique challenges due to the proximity to saltwater and high humidity levels. These environmental conditions can significantly impact the durability and longevity of building materials, particularly fencing. Thus, it is vital to select fencing materials that can withstand such harsh environments. Galvanized steel fencing has emerged as an optimal choice for coastal projects due to its inherent resistance to corrosion and degradation.

One of the primary advantages of galvanized steel is the protective layer of zinc that coats the steel. This galvanization process creates a barrier that prevents moisture from reaching the base metal, effectively reducing the risk of rust and corrosion that typically affects other materials, such as wood and untreated metal. In the harsh coastal environment, where salt particles are prevalent, galvanized steel fencing can outperform many alternatives, remaining structurally sound over time.

Furthermore, the usage of galvanized steel fencing promotes low maintenance requirements. Unlike wooden fencing, which may require frequent painting, staining, or replacement due to rot and decay from moisture exposure, galvanized steel typically requires minimal upkeep. This characteristic not only saves time but also reduces long-term costs for construction projects, making it an economically favorable option. Additionally, galvanized steel is highly durable; it can withstand the physical forces from high winds or storms, which are common in coastal regions.

Lastly, aesthetic versatility is another advantage offered by galvanized steel fencing. It can be designed in various styles that complement coastal urban designs, making it an attractive option for project developers. By choosing galvanized steel fencing, construction projects in coastal areas can enhance not only functionality but also visual appeal. Its resilience against corrosion, low maintenance, and ability to withstand adverse weather conditions make galvanized steel the preferred choice for coastal fencing solutions.

Advantages of Galvanized Steel Fencing in Industrial Applications

Galvanized steel fencing has become an essential component in industrial applications due to its numerous advantages. One of the primary benefits is enhanced security. Industrial sites often contain valuable equipment and materials, making them attractive targets for theft and vandalism. Galvanized steel fencing provides a robust physical barrier that deters unauthorized access, thus protecting assets and ensuring operational continuity.

In addition to security, the safety of personnel is paramount in industrial settings. Galvanized steel fences can help to delineate hazardous areas, ensuring that employees remain within safe zones and are kept away from potential dangers associated with machinery, chemicals, and other risks. This clear demarcation minimizes the likelihood of accidents, thereby contributing to a safer work environment.

Cost-effectiveness is another significant advantage of galvanized steel fencing. The galvanization process involves coating steel with a layer of zinc, which effectively prevents rust and corrosion. This durability means that galvanized steel fences can withstand the rigors of harsh industrial environments, including exposure to chemicals and extreme weather conditions, thereby reducing maintenance costs over time. Additionally, the longevity of these fences means lower replacement costs as compared to non-galvanized options.

The aesthetic flexibility of galvanized steel fencing also deserves mention. Available in various designs and heights, it can suit different industrial needs while maintaining an appealing visual appearance. Furthermore, installation is generally straightforward, minimizing labor costs and downtime, which is critical in industrial settings where efficient operations are essential.

In summary, the use of galvanized steel fencing in industrial applications offers significant advantages in terms of security, safety, and cost-effectiveness, making it a superior choice for companies looking to protect their facilities and personnel while remaining budget-conscious.

Choosing the Right Supplier for Your Galvanized Steel Fencing Needs

Selecting the appropriate supplier for your galvanized steel fencing is pivotal for the success of any coastal or industrial construction project. It is essential to emphasize quality assurance, as the durability and resistance of galvanized steel to corrosion and environmental factors directly influence the long-term performance of the fencing. A reputable supplier should provide clear certifications and product specifications that attest to the quality of their materials.

When evaluating suppliers, consider their reputation within the industry. Companies with a longstanding history, such as a leading China fence company known for delivering high-quality metal fencing products, often have established relationships with clients that can serve as a testament to their reliability and effectiveness. Reviews and testimonials from previous clients can provide insights into the supplier’s professionalism, adherence to deadlines, and responsiveness to client needs.

Customer service is another critical element in the supplier selection process. Engaging with a supplier that values open communication can make the procurement process more efficient. Ask about their willingness to assist in selecting the right fencing solution tailored to your specific project requirements. A competent supplier should be proactive in providing support, including guidance on installation, maintenance, and the customization of fencing products to suit unique needs.

It is advisable to establish a dialogue with potential suppliers, discussing your project specifications and expectations to understand how they can meet your needs. Inquire about their after-sales service policies, as ongoing support can be crucial for maintenance and any future requirements. Ultimately, finding the right galvanized steel fencing supplier ensures that you will receive not only superior products but also the support necessary for the successful execution of your construction project.