Introduction to Chain Link Fencing

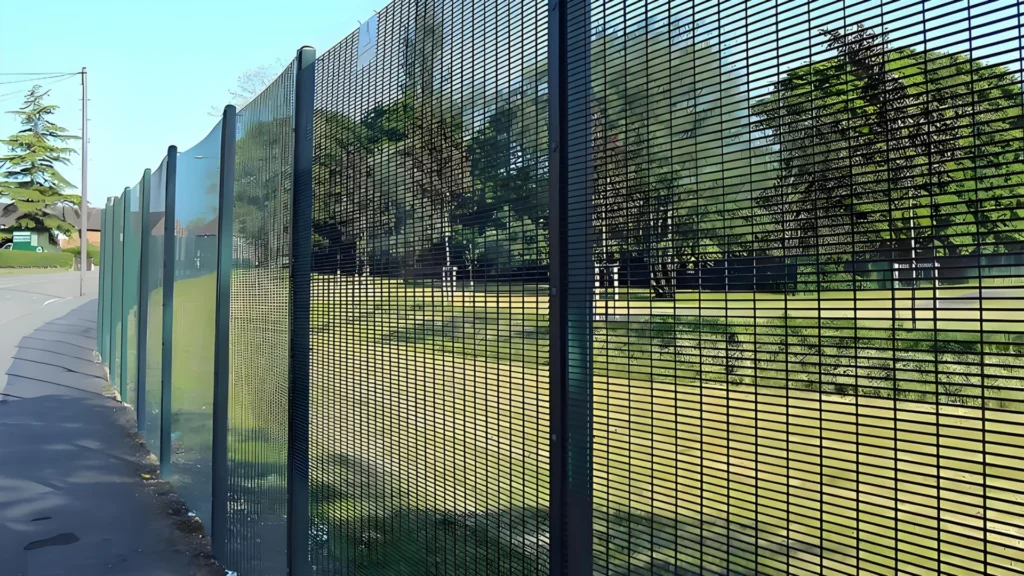

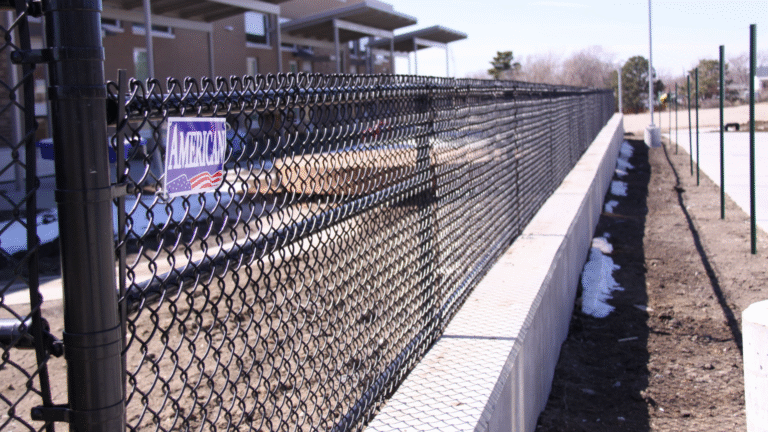

Chain link fencing is a widely utilized barrier system composed primarily of galvanized steel wire that is woven together to form a diamond pattern. This specific construction results in a highly durable and versatile fencing solution, applicable in multiple settings across various industries. The materials used in chain link fences can vary, but they predominantly consist of steel coated with zinc to enhance resistance against corrosion and weathering.

The properties of chain link fencing make it an attractive choice for both residential and industrial applications. Its open structure allows for visibility and airflow while still providing a strong physical barrier. Chain link fences are available in different heights and gauges, accommodating a range of security needs. Furthermore, modifications, such as slats or barbed wire, can be added to increase privacy or security. These qualities contribute to the overall reputation of chain link fencing as a practical and cost-effective solution.

In addition to their use in residential properties, chain link fences are commonly employed in commercial environments, public spaces, and industrial sectors. They serve crucial roles in sectors that demand robust perimeter control, including schools, parks, and construction sites. The combination of ease of installation and maintenance ensures that chain link fences remain a preferred choice for property demarcation and security. This adaptability is particularly pertinent in the oil industry, where fencing must meet specific regulatory requirements while also safeguarding sensitive areas. The resilience and longevity of chain link fences make them well-suited to withstand challenging environments found in oil extraction and refining operations.

Safety and Security Measures

Chain link fences play a critical role in ensuring safety and security within the oil industry, particularly at oil fields and refineries where the potential for hazards is significant. These robust structures serve as a clear delineation of boundaries, effectively marking off limits to unauthorized personnel. Their visibility is one of their primary strengths, as the interwoven mesh allows for enhanced surveillance, aiding personnel in monitoring the area for any unauthorized access.

In addition to deterring trespassers, chain link fences contribute significantly to the enforcement of safety protocols in hazardous environments. By defining a secure perimeter, these fences help ensure that workers and equipment remain in designated safe zones, thus minimizing the risk of accidents. In oil production areas, where various materials and processes can pose significant risks, maintaining a secure barrier is essential. This protective measure assists in fulfilling regulatory requirements established for the safety of both personnel and property.

Moreover, the oil industry faces ongoing threats, such as theft of equipment and resources, which can lead to severe economic losses. Chain link fences are a cost-effective solution to bolster security against such threats. When combined with additional security measures like surveillance cameras or alarm systems, they form a comprehensive approach to perimeter security. The fences themselves require consistent maintenance to ensure their integrity and effectiveness; any breach or deterioration could compromise safety and security efforts.

Hence, the implementation of chain link fencing is a vital component of the oil industry’s safety and security framework. By effectively managing access and protecting designated areas, these fences play a significant role in mitigating risks associated with both unauthorized entry and potential accidents, ultimately ensuring the safety of both personnel and operations in the oil industry.

Environmental Considerations

Chain link fences play a pivotal role in the oil industry, particularly regarding environmental safety. These fences serve as barriers that can effectively contain spills or hazardous materials, thereby preventing contamination of the surrounding ecosystem. In regions where oil extraction occurs, the risk of leaks or spills is ever-present. The implementation of chain link fencing around these sites is crucial in managing such risks. By forming a protective boundary, these fences help ensure that any accidental discharge is contained within a designated area, minimizing the chances of environmental degradation.

Moreover, the environmental footprint of installation practices must also be taken into account. When selecting materials for chain link fences, considerations for sustainability should be prioritized. Recyclable materials, such as galvanized steel, can be utilized to create fences that not only meet industry standards but also promote eco-friendliness. Additionally, advancements in manufacturing processes can lead to the development of materials with lower environmental impact, thereby supporting sustainability initiatives within the oil sector.

In sensitive areas, where biodiversity is at risk, the strategic placement of these fences can offer critical protection. For instance, by ensuring that oil sites are clearly delineated, chain link fencing can prevent unauthorized access, thereby reducing potential disturbances to wildlife habitats. Furthermore, thoughtful design and implementation processes can enhance the visibility of surrounding flora and fauna, which may inadvertently assist in ecological conservation efforts.

Overall, the integration of chain link fencing in the oil industry not only provides necessary safety measures but also carries the potential to significantly lessen environmental impacts. By prioritizing sustainable materials and mindful installation techniques, the oil industry can address ecological concerns while still fulfilling its operational requirements.

Benefits and Challenges of Chain Link Fences in Oil Operations

Chain link fences provide numerous benefits in the oil industry, making them an essential component of security and operational efficiency. One notable advantage is their cost-effectiveness. Compared to other fencing options, chain link fences are relatively affordable to install. The materials used are less expensive, and the installation process generally requires less labor, thus lowering overall costs. This affordability is critical in an industry where budget constraints often dictate operational decisions.

Durability is another significant benefit of chain link fences. Constructed from galvanized steel or vinyl-coated wire, these fences are designed to withstand harsh environmental conditions typical in oil operations, such as exposure to chemicals, UV rays, and severe weather. Their robust nature contributes to the lasting integrity of the fencing system, minimizing the need for frequent replacements. Additionally, chain link fences offer visibility, which is crucial for monitoring activities and ensuring safety within oil fields.

However, organizations must also consider the challenges associated with chain link fences in oil operations. One primary concern is their susceptibility to corrosion, especially in corrosive environments often found in the oil industry. Even with galvanization, chain link fences may require protective coatings to ensure longevity. Regular maintenance is essential to address wear and tear, ensuring that the fences remain functional over time. Environmental factors, such as moisture and chemical spills, can accelerate degradation, necessitating a proactive approach to upkeep.

Ultimately, while chain link fences present certain challenges, their cost-effectiveness, durability, and ease of installation render them a practical choice for oil operations. Regular maintenance and protective measures can mitigate potential drawbacks, solidifying their role in maintaining secure and efficient oil production environments.