Knowing Our Metal Fence Manufacturing Process

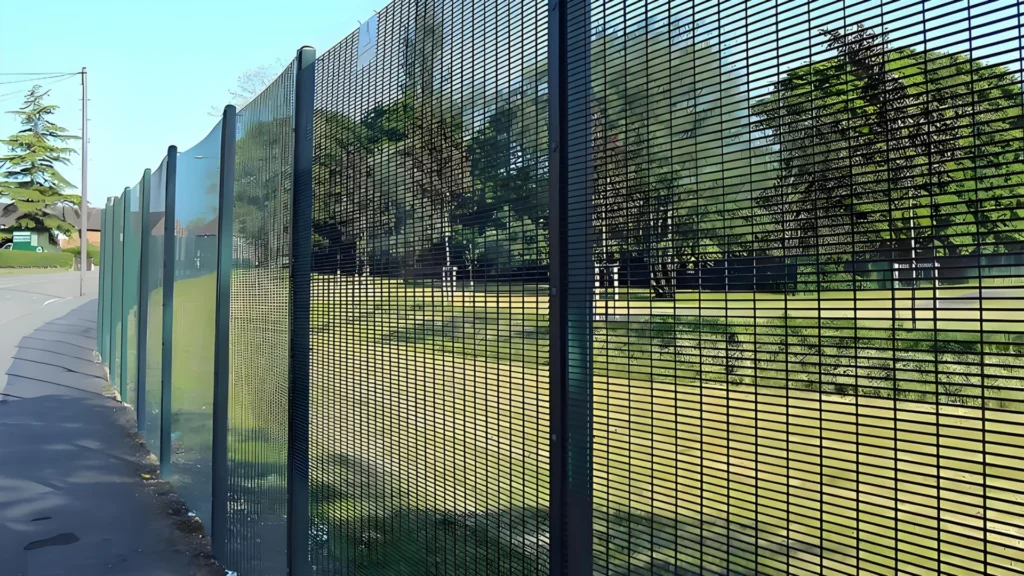

At our state-of-the-art metal fence factory, we are proud of ourselves on creating high-quality, customized fences like chain link fences,358 clear view fences tailored to the unique needs of our clients. The journey of crafting a fence begins with a thorough consultation, where we gather valuable information about the client’s requirements, preferences, and intended applications etc.

The Workshops That Make It Happen

Our fencing facility is divided into specialized workshops, each is dedicated to a crucial aspect of the fence manufacturing process. In the design workshop, our talented engineers use advanced software like SU,Skech Up to create detailed blueprints for bespoke fence designs. This lays the groundwork for precision and attention to detail throughout the manufacturing process.

From Raw Material to Finished Product

After full approval of the designs agreed by the clients, we then will move into the fabrication phase. Here, high-quality raw materials are cut, shaped, and welded by our skilled craftspeople. The next step is involved with finishing touches, such as galvanizing or zinc coating and/or powder coating, ensuring that each fence is not only aesthetically pleasing but also durable and resistant to the elements.

Finally, every customized fencing product will undergo a rigorous quality control inspection like sincere invitation to our factory in Raoyang County,Hengshui City,Hebei Province before it is packaged and shipped to the client’s port. With an efficient combination of modern technology and traditional craftsmanship, our high quality metal fence factory is ready to meet the fencing project needs of our valued customers, which is ensuring their vision that become a reality.For custom fencing goods,please add our WhatsApp:+86 138 1087 4664