Key Factors Influencing Metal Fencing Quotations: A Guide for Efficient Client Collaboration

In the metal fencing industry, quotations are not just numerical responses—they are the result of precise matching between client needs and product specifications. Lately, many suppliers have encountered a common challenge: potential clients, especially traders less familiar with fencing expertise, often provide only basic information (e.g., total length, height, and fence type like chain link, 358 clear view, or 2D/3D V-bend fences) when inquiring. but in order to get accurate quotations which rely on granular, professional details—the key factors that directly determine material costs, production complexity, and final pricing. When you are understanding these key elements,it is critical for both suppliers (to avoid underquoting or overquoting) and clients (to ensure the quoted product meets project requirements without unexpected cost overruns). Below, we are breaking down the core factors shaping metal fencing quotations and offer guidance for smoother communication.

1. Fence Type: The Foundation of Initial Cost Positioning

The type of fence a client specifies sets the “baseline cost” for quotation, as different designs involve distinct manufacturing processes, material usage, and technical thresholds.

- Chain Link Fence: As a cost-effective, versatile option, it uses twisted hexagonal wire mesh and simple frame structures. Its lower production complexity means it typically has a more budget-friendly base price, suitable for general areas like residential boundaries or construction site enclosures.

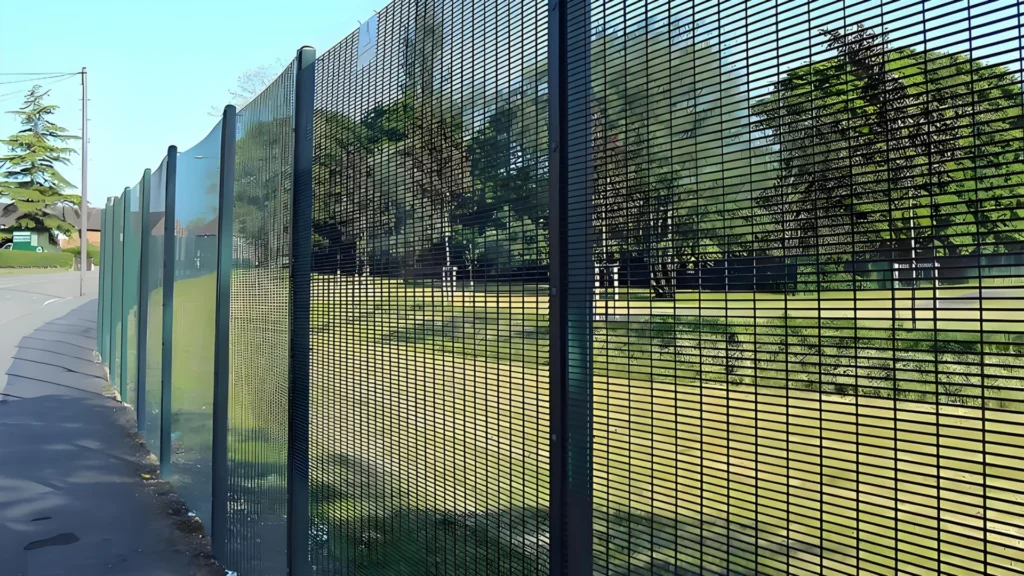

- 358 Clear View Fence: Nicknamed “anti-climb fence,” it features small mesh openings (76mm×12.5mm) and thick wire. The dense structure requires more raw materials and precision welding, making its base cost significantly higher than chain link fences. It is often used in high-security scenarios (airports, prisons, or industrial zones), so its quotation must account for anti-climb performance and material intensity.

- 2D/3D V-Bend Fence: With its aesthetic, wavy (2D) or three-dimensional (3D) bent mesh panels, this type demands additional bending and shaping processes. The 3D version, in particular, requires more complex mold design and material stress control, leading to higher production costs than flat-panel fences. It is favored for landscape projects or commercial areas, where design aesthetics add to the quotation value.

Simply stating a fence type helps suppliers narrow down the cost range, but it is only the first step—detailed specifications are needed to refine the price.

2. Core Structural Parameters: The “Weight-Bearing” Factors of Pricing

Structural parameters directly affect material consumption and product durability, making them the most critical variables in quotation calculations. For traders unfamiliar with these details, clarifying them with end-users (or consulting suppliers) is essential.

A. Wire Diameter: More Than Just “Thickness”

Wire diameter (measured in mm) determines the amount of raw material used and the fence’s tensile strength. Even a 0.5mm difference can lead to a noticeable cost gap:

- For example, a chain link fence with 3.55/4.75mm diameter wire uses at least 20% more steel per square meter than one with 2.5mm wire. Over a 1,000-meter project, this difference translates to hundreds of kilograms of additional material cost,and people who are not insiders seldom know it.

- For high-security fences like 358, wire diameter is often standardized (e.g., 4.0mm for mesh wires), but deviations from this standard (e.g., 4.5mm for extra strength) will immediately increase the quotation.

Suppliers cannot accurately calculate material costs without knowing the exact wire diameter—estimating based on “average thickness” risks either losing profit or providing an uncompetitive price.

B. Post Specifications: The “Backbone” of Cost

Fence posts (the vertical supports for fence panels) are another major cost factor, with two key parameters: wall thickness and material grade like Q235 for example.

- Wall Thickness: Common post thicknesses range from 1.2mm to 3.0mm. A 2.0mm thick fence post (e.g., for 2.0m high 3D V-bend fences) uses ~60% more steel than a 1.2mm thick post of the same length. The thicker posts are required for tall fences (over 2.5m) or windy areas (to resist lateral pressure), the more it will raise material costs.

- Material Grade: Posts made of Q235 steel (general-purpose) are more affordable than those made of Q355 steel (high-strength), which is used for heavy-duty scenarios like highway guardrails. Confusing these grades will lead to inaccurate pricing.

C. Mesh Size (For Mesh Fences)

Mesh size (e.g., 50×50mm for chain link, 76×12.5mm for 358) affects both material usage and production efficiency:

- Smaller mesh sizes (e.g., 358’s 76×12.5mm) require more wire to weave the same area, increasing material costs. They also take longer to produce (more weaving steps), raising labor or machine time costs.

- Larger mesh sizes (e.g., 100×100mm for chain link) reduce material consumption but may not meet security requirements—so quotation must balance mesh size with the client’s actual needs (e.g., preventing small animals vs. anti-climb).

3. Surface Treatment: Corrosion Resistance = Long-Term Cost, Reflected in Quotations

Metal fencing’s lifespan depends heavily on surface treatment, and different treatments have vastly different cost implications. The most common options are hot-dip galvanizing (often mentioned by suppliers) and powder coating/liquid painting.

Hot-Dip Galvanizing Weight: The “Anti-Rust Insurance”

Galvanizing weight (measured in g/㎡) indicates the thickness of the zinc layer on the fence surface—directly related to corrosion resistance and cost:

- Standard galvanizing weight for general outdoor use is 60-80g/㎡ at least. For some harsh environments (for example coastal areas with salt spray, or industrial zones with chemicals), 120-180g/㎡ or even more weight is required.

- The cost of 120g/㎡ galvanizing is about 30% higher than 80g/㎡, as it requires longer immersion time in the zinc bath and more zinc consumption,that will guarantee long time of using.

Traders often overlook this parameter, but a fence with insufficient galvanizing will rust very quickly, leading to rework or complaints—making galvanizing weight a non-negotiable detail for accurate quotations for sure.

Powder Coating/Liquid Painting

If the client requires a specific color (e.g., RAL 9002 white for municipal projects), powder coating or liquid painting is added to the galvanized surface. Costs vary by:

- Coating Thickness: 60-80μm (standard) vs. 100μm (extra durable) increases material cost by ~25%.

- Color Specialization: Custom colors (not in the supplier’s standard palette) require custom powder mixing, adding extra fees.

4. Easy-to-Ignore Additional Costs: Avoid “Hidden Surprises”

Quotations are not just about the fence itself—logistics, accessories, and services often account for 10-20% of the total cost. These details are especially important for traders who need to calculate landed costs for end-users.

- Accessories: Fence installation requires hardware like bolts, nuts, washers, and post caps. For example, stainless steel bolts (rust-resistant) cost 2-3 times more than carbon steel bolts. A 1,000-meter fence may need 500+ sets of accessories—omitting this from the quotation will lead to cost leakage.

- Logistics: As discussed in previous communications, “land + ocean freight” depends on the destination (e.g., inland vs. coastal ports), container type (40ft HC vs. 20ft), and cargo weight (as in the 24.7-ton, 2-container example). Traders should provide the final delivery address to suppliers for CIF’s accurate logistics cost calculation.

- Installation & After-Sales: If the client requires on-site installation, costs include labor, tools, and travel expenses. After-sales services (e.g., 1-year corrosion warranty) may also affect the quotation as well, as suppliers need to account for potential maintenance costs in the future.The fencing products made by ChinaFenceCompany are higher quality.

- Taxes & Duties: For international fence orders, import duties of goods, VAT, and customs clearance fees must be clarified—these can add 5-15% to the total cost, depending on the country/region.

Guidance for Traders: How to Collect Information for Accurate Quotations

For traders less familiar with fencing technicalities, bridging the “knowledge gap” with end-users and suppliers is key to smooth quotation collaboration:

- Ask “Scenario-First” Questions: Instead of only asking “fence length,” ask the end-user: “What is the fence used for? (e.g., residential, airport, highway) Is it in a coastal or industrial area?” This helps suppliers recommend appropriate specifications (e.g., 358 for airports, high galvanizing weight for coasts).

- Request Reference Samples or Drawings: If the end-user cannot describe parameters, ask for photos of similar fences or basic drawings (even hand-drawn) indicating wire thickness, post size, and color.

- Leverage Supplier Expertise: Share the limited information you have with suppliers (e.g., “1,000m fence for a residential community”) and ask for a “specification checklist”—most suppliers will provide a form listing wire diameter, galvanizing weight, etc., to help you collect details from end-users.

Conclusion: Precision in Details = Win-Win Collaboration

Accurate metal fencing quotations are not built on rough estimates, but on clear communication of technical parameters. For suppliers, clarifying key factors (fence type, structural parameters, surface treatment, and additional costs) ensures quotations are both competitive and profitable. For traders, collecting detailed information (with the help of suppliers) avoids misunderstandings with end-users and prevents cost overruns or product mismatches.

In the end, every parameter—from a 0.5mm wire diameter to a 20g/㎡ galvanizing weight—matters. By focusing on these key factors, suppliers and traders can build trust, streamline the quotation process, and lay the groundwork for successful project execution.